Zero-Boil-Off Tank Experiments to Enable Long-Duration Space Exploration

NASA

Do we have enough fuel to get to our destination? This is probably one of the first questions that comes to mind whenever your family gets ready to embark on a road trip. If the trip is long, you will need to visit gas stations along your route to refuel during your travel. NASA is grappling with similar issues as it gets ready to embark on a sustainable mission back to the Moon and plans future missions to Mars. But while your car’s fuel is gasoline, which can be safely and indefinitely stored as a liquid in the car’s gas tank, spacecraft fuels are volatile cryogenic liquid propellants that must be maintained at extremely low temperatures and guarded from environmental heat leaks into the spacecraft’s propellant tank. And while there is already an established network of commercial gas stations in place to make refueling your car a cinch, there are no cryogenic refueling stations or depots at the Moon or on the way to Mars. Furthermore, storing volatile propellant for a long time and transferring it from an in-space depot tank to a spacecraft’s fuel tank under microgravity conditions will not be easy since the underlying microgravity fluid physics affecting such operations is not well understood. Even with today’s technology, preserving cryogenic fuels in space beyond several days is not possible and tank-to-tank fuel transfer has never been previously performed or tested in space.

Heat conducted through support structures or from the radiative space environment can penetrate even the formidable Multi-Layer Insulation (MLI) systems of in-space propellant tanks, leading to boil-off or vaporization of the propellant and causing tank self-pressurization. The current practice is to guard against over-pressurizing the tank and endangering its structural integrity by venting the boil-off vapor into space. Onboard propellants are also used to cool down the hot transfer lines and the walls of an empty spacecraft tank before a fuel transfer and filling operation can take place. Thus, precious fuel is continuously wasted during both storage and transfer operations, rendering long-duration expeditions—especially a human Mars mission—infeasible using current passive propellant tank pressure control methods.

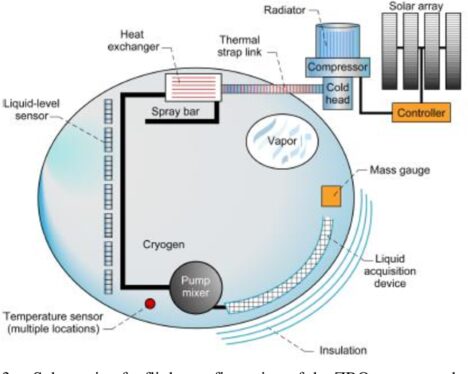

Zero-Boil-Off (ZBO) or Reduced Boil-Off (RBO) technologies provide an innovative and effective means to replace the current passive tank pressure control design. This method relies on a complex combination of active, gravity-dependent mixing and energy removal processes that allow maintenance of safe tank pressure with zero or significantly reduced fuel loss.

Zero Boil-off Storage and Transfer: A Transformative Space Technology

At the heart of the ZBO pressure control system are two proposed active mixing and cooling mechanisms to counter tank self-pressurization. The first is based on intermittent, forced, subcooled jet mixing of the propellantand involves complex, dynamic, gravity-dependent interaction between the jet and the ullage (vapor volume) to control the condensation and evaporation phase change at the liquid-vapor interface. The second mechanism uses subcooled droplet injection via a spraybar in the ullage to control tank pressure and temperature. While the latter option is promising and gaining prominence, it is more complex and has never been tested in microgravity where the phase change and transport behavior of droplet populations can be very different and nonintuitive compared to those on Earth.

Although the dynamic ZBO approach is technologically complex, it promises an impressive advantage over the currently used passive methods. An assessment of one nuclear propulsion concept for Mars transport estimated that the passive boil-off losses for a large liquid hydrogen tank carrying 38 tons of fuel for a three-year mission to Mars would be approximately 16 tons/year. The proposed ZBO system would provide a 42% saving of propellant mass per year. These numbers also imply that with a passive system, all the fuel carried for a three-year Mars mission would be lost to boil-off, rendering such a mission infeasible without resorting to the transformative ZBO technology.

The ZBO approach provides a promising method, but before such a complex technological and operational transformation can be fully developed, implemented, and demonstrated in space, important and decisive scientific questions that impact its engineering implementation and microgravity performance must be clarified and resolved.

The Zero-Boil-Off Tank (ZBOT) Microgravity Science Experiments

The Zero Boil-off Tank (ZBOT) Experiments are being undertaken to form a scientific foundation for the development of the transformative ZBO propellant preservation method. Following the recommendation of a ZBOT science review panel comprised of members from aerospace industries, academia, and NASA, it was decided to perform the proposed investigation as a series of three small-scale science experiments to be conducted onboard the International Space Station. The three experiments outlined below build upon each other to address key science questions related to ZBO cryogenic fluid management of propellants in space.

The ZBOT-1 Experiment: Self-Pressurization & Jet Mixing

The first experiment in the series was carried out on the station in the 2017-2018 timeframe. Figure 3 shows the ZBOT-1 hardware in the Microgravity Science Glovebox (MSG) unit of the station. The main focus of this experiment was to investigate the self-pressurization and boiling that occurs in a sealed tank due to local and global heating, and the feasibility of tank pressure control via subcooled axial jet mixing. In this experiment, the complicated interaction of the jet flow with the ullage (vapor volume) in microgravity was carefully studied. Microgravity jet mixing data was also collected across a wide range of scaled flow and heat transfer parameters to characterize the time constants for tank pressure reduction, and the thresholds for geyser (liquid fountain) formation, including its stability, and penetration depth through the ullage volume. Along with very accurate pressure and local temperature sensor measurements, Particle Image Velocimetry (PIV) was performed to obtain whole-field flow velocity measurements to validate a Computational Fluid Dynamics (CFD) model.

Some of the interesting findings of the ZBOT-1experiment are as follows:

- Provided the first tank self-pressurization rate data in microgravity under controlled conditions that can be used for estimating the tank insulation requirements. Results also showed that classical self-pressurization is quite fragile in microgravity and nucleate boiling can occur at hotspots on the tank wall even at moderate heat fluxes that do not induce boiling on Earth.

- Proved that ZBO pressure control is feasible and effective in microgravity using subcooled jet mixing, but also demonstrated that microgravity ullage-jet interaction does not follow the expected classical regime patterns (see Figure 4).

- Enabled observation of unexpected cavitation during subcooled jet mixing, leading to massive phase change at both sides of the screened Liquid Acquisition Device (LAD) (see Figure 5). If this type of phase change occurs in a propellant tank, it can lead to vapor ingestion through the LAD and disruption of liquid flow in the transfer line, potentially leading to engine failure.

- Developed a state-of-the-art two-phase CFD model validated by over 30 microgravity case studies (an example of which is shown in Figure 4). ZBOT CFD models are currently used as an effective tool for propellant tank scaleup design by several aerospace companies participating in the NASA tipping point opportunity and the NASA Human Landing System (HLS) program.

The ZBOT-NC Experiment: Non-Condensable Gas Effects

Non-condensable gases (NCGs) are used as pressurants to extract liquid for engine operations and tank-to-tank transfer. The second experiment, ZBOT-NC will investigate the effect of NCGs on the sealed tank self-pressurization and on pressure control by axial jet mixing. Two inert gases with quite different molecular sizes, Xenon, and Neon, will be used as the non-condensable pressurants. To achieve pressure control or reduction, vapor molecules must reach the liquid-vapor interface that is being cooled by the mixing jet and then cross the interface to the liquid side to condense.

This study will focus on how in microgravity the non-condensable gases can slow down or resist the transport of vapor molecules to the liquid-vapor interface (transport resistance) and will clarify to what extent they may form a barrier at the interface and impede the passage of the vapor molecules across the interface to the liquid side (kinetic resistance). By affecting the interface conditions, the NCGs can also change the flow and thermal structures in the liquid.

ZBOT-NC will use both local temperature sensor data and uniquely developed Quantum Dot Thermometry (QDT) diagnostics to collect nonintrusive whole-field temperature measurements to assess the effect of the non-condensable gases during both self-pressurization heating and jet mixing/cooling of the tank under weightlessness conditions. This experiment is scheduled to fly to the International Space Station in early 2025, and more than 300 different microgravity tests are planned. Results from these tests will also enable the ZBOT CFD model to be further developed and validated to include the non-condensable gas effects with physical and numerical fidelity.

The ZBOT-DP Experiment: Droplet Phase Change Effects

ZBO active pressure control can also be accomplished via injection of subcooled liquid droplets through an axial spray-bar directly into the ullage or vapor volume. This mechanism is very promising, but its performance has not yet been tested in microgravity. Evaporation of droplets consumes heat that is supplied by the hot vapor surrounding the droplets and produces vapor that is at a much lower saturation temperature. As a result, both the temperature and the pressure of the ullage vapor volume are reduced. Droplet injection can also be used to cool down the hot walls of an empty propellant tank before a tank-to-tank transfer or filling operation. Furthermore, droplets can be created during the propellant sloshing caused by acceleration of the spacecraft, and these droplets then undergo phase change and heat transfer. This heat transfer can cause a pressure collapse that may lead to cavitation or a massive liquid-to-vapor phase change. The behavior of droplet populations in microgravity will be drastically different compared to that on Earth.

The ZBOT-DP experiment will investigate the disintegration, coalescence (droplets merging together), phase change, and transport and trajectory characteristics of droplet populations and their effects on the tank pressure in microgravity. Particular attention will also be devoted to the interaction of the droplets with a heated tank wall, which can lead to flash evaporation subject to complications caused by the Liedenfrost effect (when liquid droplets propel away from a heated surface and thus cannot cool the tank wall). These complicated phenomena have not been scientifically examined in microgravity and must be resolved to assess the feasibility and performance of droplet injection as a pressure and temperature control mechanism in microgravity.

Back to Planet Earth

This NASA-sponsored fundamental research is now helping commercial providers of future landing systems for human explorers. Blue Origin and Lockheed Martin, participants in NASA’s Human Landing Systems program, are using data from the ZBOT experiments to inform future spacecraft designs.

Cryogenic fluid management and use of hydrogen as a fuel are not limited to space applications. Clean green energy provided by hydrogen may one day fuel airplanes, ships, and trucks on Earth, yielding enormous climate and economic benefits. By forming the scientific foundation of ZBO cryogenic fluid management for space exploration, the ZBOT science experiments and CFD model development will also help to reap the benefits of hydrogen as a fuel here on Earth.

PROJECT LEAD

Dr. Mohammad Kassemi (Dept Mechanical & Aerospace Engineering, Case Western Reserve University)

SPONSORING ORGANIZATION

Biological and Physical Sciences (BPS) Division, NASA Science Mission Directorate (SMD)