5 min read

Preparations for Next Moonwalk Simulations Underway (and Underwater)

Establishing sustained operations at the Moon and Mars presents a multitude of opportunities and challenges NASA has yet to encounter. Many of these activities require new technologies and processes to ensure the agency is prepared for its ambitious Artemis missions and those beyond.

One of those challenges is working with cryogenic fluids, meaning fluids existing in a liquid state between minus 238 degrees Fahrenheit and absolute zero (minus 460 F). These fluids – liquid hydrogen (the most difficult to work with), methane, and oxygen – are vital to spacecraft propulsion and life support systems. The fluids may also be produced in the future on the lunar and Martian surfaces via in-situ resource utilization (ISRU).

Human exploration in deep space requires storing large amounts of cryogenic fluids for weeks, months, or longer, as well as transferring between spacecraft or fuel depots in orbit and on the surface. Each aspect is challenging, and, to date, large amounts of cryogenic fluids have only been stored for hours in space. Engineers working in NASA’s Cryogenic Fluid Management (CFM) portfolio – led by Technology Demonstration Missions within the Space Technology Mission Directorate and managed at the agency’s Glenn Research Center in Cleveland and Marshall Space Flight Center in Huntsville, Alabama – are solving those issues ahead of future missions.

“This is a task neither NASA, nor our partners, have ever done before,” said Lauren Ameen, deputy CFM Portfolio manager. “Our future mission concepts rely on massive amounts of cryogenic fluids, and we have to figure out how to efficiently use them over long durations, which requires a series of new technologies far exceeding today’s capabilities.”

Cryogenic Challenges

For a cryogenic fluid to be useable, it must remain in a frigid, liquid state. However, the physics of space travel – moving in and out of sunlight and long stays in low gravity – make keeping those fluids in a liquid state and knowing how much is in the tank complicated.

The heat sources in space – like the Sun and the spacecraft’s exhaust – create a hot environment inside and around storage tanks causing evaporation or “boiloff.” When fluid evaporates, it can no longer efficiently fuel a rocket engine. It also increases the risk of leakage or, even worse, a tank rupture.

Being unsure of how much gas is left in the tank isn’t how our explorers want to fly to Mars. Low gravity is challenging because the fuel wants to float around – also known as “slosh” – which makes accurately gauging the amount of liquid and transferring it very difficult.

“Previous missions using cryogenic propellants were in space for only a few days due to boiloff or venting losses,” Ameen noted. “Those spacecraft used thrust and other maneuvers to apply force to settle propellant tanks and enable fuel transfers. During Artemis, spacecraft will dwell in low gravity for much longer and need to transfer liquid hydrogen in space for the first time, so we must mitigate boiloff and find innovative ways to transfer and measure cryogenic propellants.”

So, What’s NASA Doing?

NASA’s CFM portfolio encompasses 24 development activities and investments to reduce boiloff, improve gauging, and advance fluid transfer techniques for in-space propulsion, landers, and ISRU. There are four near-term efforts taking place on the ground, in near-Earth orbit, and soon on the lunar surface.

Flight Demos

In 2020, NASA awarded four CFM-focused Tipping Point contracts to American industry – Eta Space, Lockheed Martin, SpaceX, and United Launch Alliance – to assist in developing and demonstrating CFM technologies in space. Each company is scheduled to launch its respective demonstration in either 2024 or 2025, performing multiple tests using liquid hydrogen to validate technologies and processes.

Radio Frequency Mass Gauge

To improve gauging, NASA has developed Radio Frequency Mass Gauges (RFMG) to allow for more accurate fluid measurement in low-gravity or low-thrust conditions. Engineers do this by measuring the electromagnetic spectrum, or radio waves, within a spacecraft’s tank throughout the mission, comparing them to fluid simulations to accurately gauge remaining fuel.

The RFMG has been proven in ground tests, sub-orbital parabolic flight, and on the International Space Station, and it will soon be tested on the Moon during an upcoming Commercial Lunar Payload Services flight with Intuitive Machines. Once demonstrated in the lunar environment, NASA will continue to develop and scale the technology to enable improved spacecraft and lander operations.

Cryocoolers

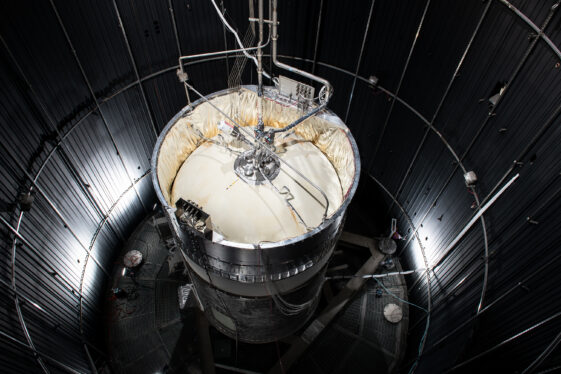

Cryocoolers act like heat exchangers for large propellant tanks to mitigate boiloff when combined with innovative tank insulation systems. With industry partners, like Creare, NASA has begun testing high-capacity cryocooler systems that pump the “working” fluid through a network of tubes installed on the tank to keep it cool. NASA plans to increase tank size and capabilities to meet mission requirements before conducting future flight demonstrations.

CryoFill

NASA is also developing a liquefaction system to turn gaseous oxygen into liquid oxygen on the surface of the Moon or Mars to refuel landers using propellant produced in situ. This approach uses various methods to cool oxygen down to critical temperature (at least minus 297 degrees Fahrenheit), where it condenses, turning from a gas to a liquid. Initial development and testing have proven NASA can do this efficiently, and the team continues to scale the technology to relevant tank sizes and quantities for future operations.

Ultimately, NASA efforts to develop and test CFM systems that are energy-, mass-, and cost-efficient are critical to the success of the agency’s ambitious missions to the Moon, Mars, and beyond.